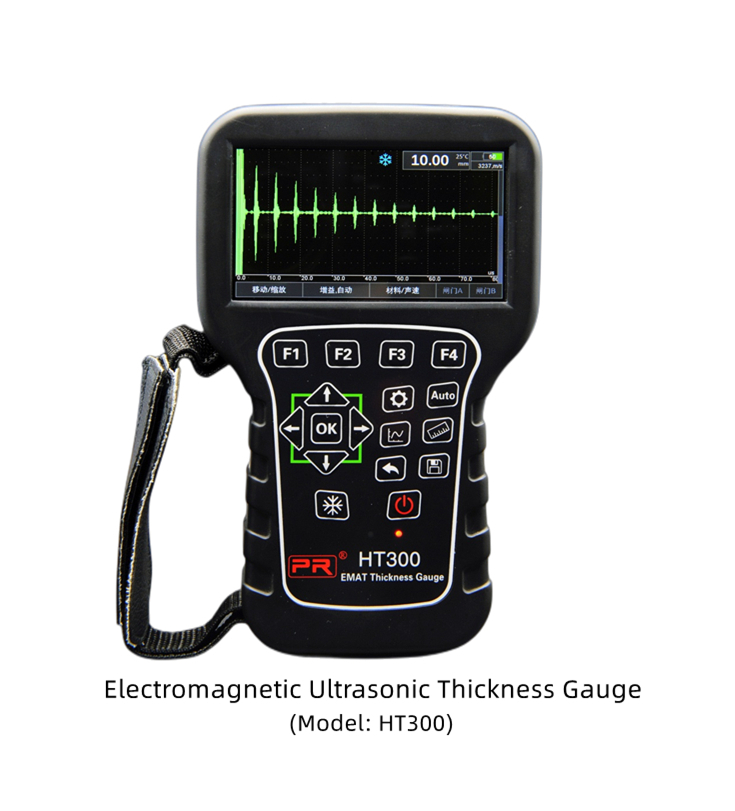

EMAT Thickness Gauge

Electromagnetic Ultrasonic

Thickness Gauge (Model: HT300)

HT300 electromagnetic ultrasonic thickness guage adopts the advanced technology of non-contact electromagnetic ultrasound, which does not require the application of couplant or polishing the workpiece surface during detection. In contrast, it allows the detection to happen on surfaces where there are paint, rust and irregularity, and has a high lift-off distance, especially suitable for detection under high temperature environment. Materials that can be detected include conductive or magnetic materials such as carbon steel, low alloy steel, stainless steel, special steel, cast iron, aluminum alloy and titanium alloys.

<<< Company's product

<<< Detection characteristics

- No application of couplant and polishing of workpiece surface is required. The surface to be tested is allowed to have paints, clads and bumps.

- Non-contact lift-off distance is greater than 6mm.

- Thickness measurement range is 2mm~120mm. Other thickness range can be customized.

- Allow direct reading of temperature, with sound velocity compensation under high temperature.

- Output of thickness value through serial port.

- Suitable for thickness corrosion detection under high temperature environments. The temperature range is -40 ℃ ~ 800 ℃, and higher temperature range can be customized.

- The ultrasonic wave excited is the shear wave, with high measurement accuracy (the shear wave velocity of metal material is about half the longitudinal wave velocity).

- The workpiece materials that can be detected are conductive or magnetic materials, including low carbon steel, alloy steel, stainless steel, special steel, cast iron, aluminum alloy, titanium alloy, etc.

<<< Technical parameters

|

Name |

Parameter |

Name |

Parameter |

|

Lift-off distance |

Carbon steel: greater than 6 mm |

Transmitting frequency |

2MHz~5MHz 0.005+0.1%× measured thickness |

|

Measurement range |

Carbon steel 2mm~120mm, customization available; |

Thickness accuracy |

Carbon steel under room temperature ± (0.01+2‰× thickness) mm |

|

Working mode |

A-scan/ (A-scan + thickness curve)/ thickness curve |

External encoder/data storage/sound velocity calibration |

Supported |

|

Tested radius of curvature |

Carbon steel ≥10mm |

Temperature range of workpiece tested |

-40℃~800℃, customization available |

|

Power supply mode |

Internal power supply by lithium battery |

Working time |

≥8 hours |

|

Size |

About 200mm×123mm×35mm |

Weight |

≤700g |

<<< Application fields

- Petroleum and natural gas chemical industry, such as petroleum pipelines, natural gas pipelines, oil storage tanks, chemical containers, pressure vessels, etc.;

- Steel industry, such as steel plate, steel pipe, etc.;

- Wind power industry, such as bolt tensile length;

- Ship industry, such as hull, boat deck, etc.;

- Thermal power plant industry, such as heat-exchanger tube, boiler, etc.;

Customer product registration

WRITE A MESSAGE TO US

Hot products

Suzhou Phaserise Technology Co, Ltd.

Mr. Shen

Mobile:+86-15150126158

Tel: +86-512-65022999-811 / 812

Email:sales@phaserise.com

Address:

No. 188 Chuangyuan Rd., 4th Floor Building A,

Suzhou Industrial Park,

China (Jiangsu) Pilot Free Trade Zone Suzhou Area

Wuhan Subsidiary

Tel:027-87186680

Mobile:15150126158

Address: No.14, 16th floor,Lianfeng Building, Lumo Road, Hongshan District, Wuhan City

Official wechat

Product registration form

Copyright © Suzhou Phaserise Technology Co,Ltd. 鄂ICP备19434917号-1 Powered by www.300.cn